Installation Service Available in Los Angeles And (Surrounding Areas)

* Professionally Installed

* All Work 110% Guaranteed

* Liability Job Insurance

(Very Important)

* Guaranteed Pricing

* Best Effective Job

Security Fence Wire

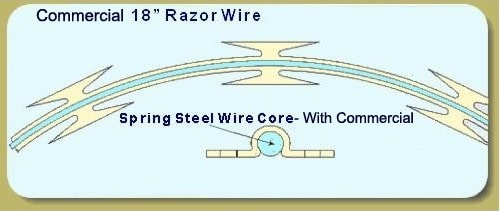

USA Made Quality w/Steel Coil

Top of Wall

Razor Wire Coil

Razor Fence

Olympic Style Rings

Razor Fence w/ Gate

Top 5 Razor Wire Installers

Some of our Clients - In The Los Angeles Area

- Walmart - La Habra

- Walmart - Pomona

- Home Depot - Bell

- Southland - Cudahy

- Family Health - Banning

- Servpro - Rancho Cucamonga

- Coastal - Vernon

- Artic Glacier Ice - Vernon

All Our Work is 110% Guaranteed

Types of Concertina Razor Wire

Now, concertina wire can be flat or coiled type and then again it could have single or double coils. Double concertina wires are made with two pieces of stainless steel razor wire or with zinc coated razor wire; which are bound together for more strength.

Single Coil Razor Wire Concertina

This is basically a hot dipped galvanized steel plate with strip processed razor wire coils which are extended in spiral type. Clips are generally not needed for this type.

Large Coils Crossed

Crossed spirals of razor wire are clipped together.

Y Post Supported Concertina Wire Fences

Concertina wires are mounted on top of a Y fence post.

Electrified Concertina Wire

These are also called electrified safety fences. These are used along with electric power for enhanced security. A copper wire is placed inside the core wire of the razor blade.

Razor Wire Mobile Obstacle Barriers /Concertina Wire used for Military

Concertina wire or crossed razor wire are used for military purposes as it can be mobile and installed fast and easy.

How we do the Concertina Razor Wire Installation

We would like to take you through a step by step process of our concertina razor wire installation. Now, before we start with the installation there a couple of points that we take care of.

Placement of the material

The material can be installed either on the ground or on the top of an adjoining pole, on the fence or against the fence. Each type of installation would be unique.

Spacing of the coil

Measure the space between one clip and the adjoining one. This determines the spacing between the coils. Usually a spacing of 12” is done with a plus or minus of 2 inches variance. Hence consistency is the key.

Attachments

Usually concertina wire is attached every four feet to the adjoining role and on every foot to the fence. It can be attached with stainless steel rebar ties or with hog rings. Rebar ties generally reduce any vibrations but it does take a little longer to install.

Now, let’s talk about the installation process-

Step 1

Along the fence line arrange the coils. The deployment for each coil needs to be decided. This would depend on the spacing of the coil and the number of coils per roll.

Step 2

Place the coil on its side and then remove the wire ties and discard them.

Step 3

Hold the coil steadily and place it along the length of the fencing line. This is where we begin stretching.

Step 4

Use around six coils and allow them to spring free from the spool which is closest to the starting point. Then these are to be attached to the fence keeping centers of approximately 6 inches.

Step 5

Once the spool has been anchored, take three coils on the other end of the spool. Grasp all three firmly and spread these about one foot from the spool.

Step 6

Grasping all the three spools start stretching the wire. We maintain a distance from the fence as well as the concertina wire to avoid any kind of snags.

Step 7

During the pulling process, shake it gently so as to free any snags between any of the coils. It does happen that barb can get entangled. If it happens, then separate by grasping firmly and spreading them apart. But while we are correcting this, we make sure that there is no one else moving the materials.

Step 8

When we are pulling the concertina wire along the fence line, there should be another installer to assure the coil spacing consistency by pulling and lifting the materials.

Step 9

We hog ring the ribbon to the chain link fabric, once the concertina wire is in place. It is possible that we might have to twist the coil so that the ribbon is lined up with the chain link weave.

Once all the above steps are completed you will have your well secured razor wire fence.

Our razor wire products are made in the United States – NOT in China — and they exceed Federal and state industrial specifications for quality. The enclosed spring steel core makes them harder to cut or bend, bringing unrivaled security to properties like equipment yards, construction sites, and military installations. You can buy the best quality concertina razor wire rolls online at Order Razor Wire Online